Exposed Aggregate Concrete: Why You Need It For Your Next Project

All About Limestones: Characteristics, benefits, and effects

September 28, 2021

Reasons Why You Should Have a High-Quality Outdoor Living Space

March 24, 2022Due to its visual appeal and longevity, exposed aggregate concrete has become a popular decorative concrete option. This is a cost-effective alternative for ornamental concrete around the home because it is entirely customised and straightforward to install.

If you’re currently planning a project and are unsure which material to utilise, continue reading. The purpose of this post is to discuss exposed aggregate concrete and why you should employ it on your next project.

What is Exposed Aggregate Concrete?

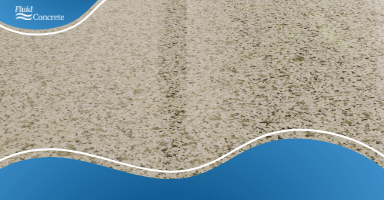

Exposed aggregate concrete is essentially identical to a polished piece of granite or marble. This material is a mundane, unimpressive surface that reveals an extraordinary beauty. The appearance is achieved by using decorative aggregate, which can be natural or manufactured.

The decorative method of exposing aggregate has been around since the early 1900s, long before pattern stamping, stencilling, and decorative overlays became popular, and it remains popular until now.

Furthermore, an exposed aggregate finish has many benefits, and many decorative concrete contractors are coming up with new ways to take exposed aggregate to a whole new level.

How Do You Expose Aggregate?

To create an exposed-aggregate surface, you have to pour concrete and then scrape away the outer skin of cement paste to reveal coarse decorative aggregate.

There are numerous methods for exposing the aggregate in concrete. Still, a typical rule of thumb is to remove the surface cement paste no deeper than one-third the diameter of the aggregate.

Application of Surface Retardant

Surface retardant sprays are sprinkled on the top layer of cement paste after the concrete has been placed to keep the surface soft and prevent the aggregates from being dislodged when the concrete cures. Using either a power washer, garden hose, or a brush and bucket of water, remove the cement paste top layer once it has dried thoroughly and hardened.

Abrasive Blasting

Abrasive blasting, such as sandblasting or shot blasting, can be used to expose the aggregate after the concrete has hardened and been set. However, this procedure is not suggested if you want to preserve the exposed aggregate’s colour and shape because it can break and diminish the entire look.

Brushing and Washing

Spraying the surface with water and brushing it with a broom removes a thin layer of the cement paste and exposes the desired depth of aggregate. This process can commence as soon as surface cement can be removed without dislodging or overexposing the aggregate. For an easy way to see whether the concrete is ready to pour, use a stiff nylon-bristled broom and lightly brush away a tiny patch of the surface cement paste to check.

What Are The Advantages of Having Exposed Aggregate Finishes?

Since exposed aggregate finishes require only a few more materials and techniques, you can accomplish amazing effects at a reasonable cost. Additionally, the fundamental methods are simple enough for experienced finishers to understand readily.

Suppose you ever want to put your own twist on it or push the boundaries and be creative. In that case, numerous types and sizes of decorative aggregate are available to create an infinite number of colour and texture variants. Exposed aggregate is highly adaptable and complements plain concrete and other decorative treatments such as stamping, stencilling, staining, and integrated colouration nicely. Most importantly, this material requires little maintenance beyond sealing and occasional cleaning.

Types of Exposed Aggregate

- Standard

This is the most commonly used method for exposing the aggregate in a concrete mix. First, the aggregate in the concrete mix must be mixed or batch-mixed at the concrete plant before the concrete can be delivered and laid at the project site.

- Polished

Meanwhile, polished exposed aggregate concrete is the most widely used technique for exposed aggregate concrete in residential settings. This method is very similar to the standard and topping methods in execution. A grinder or a sander is used to work the top layer down rather than leaving the aggregate exposed with a rough, slip-resistant surface as in traditional paving. It is necessary to apply many clear coats of sealer to get a bright, polished finish. However, if you want a matte look, you can omit this step entirely.

- Seeded

Pre-mixed exposed aggregate is carried to the job site. In contrast, seeded aggregate is hand seeded during the concrete placing process, providing a more customised appearance. For the seeded method, the decorative aggregates are placed by hand or broadcast on the surface of the freshly-poured concrete and then floated into the concrete by hand.

- Topping

This approach, also known as a concrete overlay, is used to improve the appearance of existing concrete that is still in good structural condition. In a concrete overlay batch, aggregates are combined with other ingredients and put on an existing concrete slab in a thin layer 1 to 1.5 inches thick.

Hiring a Professional

Exposed aggregate concrete is an excellent choice for anyone who wants a cost-effective, durable, and beautiful solution. This work must be done by people who know what they’re doing because there could be problems in the future if it isn’t installed correctly.

At Fluid Limestone in Perth, Western Australia, we specialise in liquid limestone and exposed aggregate Perth surfaces for roads, gardens, backyards, pool surrounds, patios, and walks. Whatever type of external renovation project you have in mind, we can assist you in achieving exceptional results while staying within your budget constraints.

We provide a broad range of professional concrete services to customers in and around Perth, emphasising exposed aggregate, honed aggregate, and liquid limestone.